Overview of Non-Stick Release Agents

Non-stick release agent is mainly added to emulsified asphalt to enhance the strength of the residue and improve the bonding performance. After the emulsified asphalt is demulsified, the non-stick wheel agent forms a protective film, increasing the stiffness modulus while reducing the adhesion with the tire. It is the main modified material of non-stick to the wheel emulsified asphalt.

Application Scenario

Tack coat, ultra-thin topcoat, bridge deck waterproofing, etc.

User Guide

According to the bonding condition of the construction materials, apply the non-stick release agent at a rate of 3% to 5%. The proportion can be directly added to the emulsified asphalt.

Production process

Weigh 500g of the compounded asphalt and heat it to 160℃. Add 15g of LT-CZ3 asphalt emulsifier to 500g of tap water. Heat the soap solution to 65℃ and stir to dissolve evenly. Start the colloid mill testing machine, add the soap solution for circulation, slowly pour in the prepared asphalt, and circulate for 2 to 3 minutes. Then release the emulsified asphalt. After the emulsified asphalt cools to room temperature, add 30g of non-stick release agent. Stir evenly to obtain non-stick to the wheel emulsified asphalt.

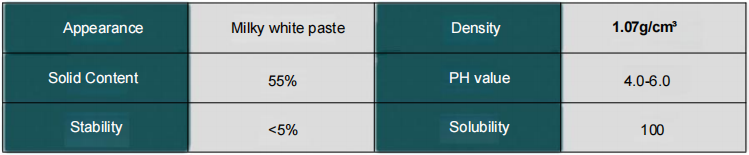

Technical Indicator